21 февраля исполнилось 90 лет члену-корреспонденту Российской академии наук, заслуженному деятелю науки РСФСР, советнику РАН, заместителю директора Института катализа СО РАН с 1961 по 1995 гг., профессору Роману Алексеевичу Буянову.

По окончании инженерного физико-химического факультета Московского химико-технологического института имени Д.И. Менделеева в 1950 г. Роман Алексеевич был направлен на Чирчикский электрохимический комбинат для участия в строительстве крупного промышленного объекта по выделению дейтерия методом ректификации жидкого водорода. Прошел путь от стажера до технического руководителя уникального, первого в мире производства тяжелого водорода. Под его непосредственным руководством строились и другие крупные промышленные объекты, такие как завод сухого льда, ТЭЦ, цех крепкой азотной кислоты.

В 1958 г. Р.А. Буянов перешел на работу в Международный Объединенный институт ядерных исследований (ОИЯИ) в г. Дубна. Здесь он занимался разработкой и промышленным освоением серийного водородно-гелиевого ожижителя, катализом при низких температурах, созданием сверхпроводящего соленоида и др.

В 1960 г. за работы в области химической технологии (разработка и промышленное освоение технологии получения дейтерия методом ректификации жидкого водорода) Р.А. Буянову присвоено звание Лауреата Ленинской премии.

В 1961 г. он защитил кандидатскую диссертацию и был приглашен Г.К. Боресковым в Институт катализа на должность его заместителя.

С августа 1961 г. Р.А. Буянов совмещал три должности: заместителя директора по науке, главного инженера и заведующего лабораторией. До 1964 г. руководил строительством Института, организацией его инфраструктуры и всех его служб. Одновременно принимал участие в решении вопросов, связанных с организацией СО АН СССР.

В 1967 г. за участие в создании Сибирского отделения АН СССР и развитие науки в Сибири награжден орденом Трудового Красного знамени.

В 1972 г. защитил докторскую диссертацию. В 1976 г. ему присвоено звание профессора, а в 1977 г. – почетное звание Заслуженный деятель науки РСФСР.

В 1979 г. Р.А. Буянов назначен руководителем Координационного центра стран СЭВ по проблеме “Разработка новых катализаторов и улучшение качества катализаторов, применяемых в промышленности”. С 1984 г. являлся представителем СССР в Совете уполномоченных стран СЭВ по этой проблеме.

В 1981 году избран членом-корреспондентом АН СССР. В 1982 г. награжден вторым орденом Трудового Красного знамени, в 1987 г. – орденом Октябрьской революции.

В 1996 г. Роман Алексеевич перешел на должность советника РАН и по-прежнему активно участвует в решении научных задач лаборатории дегидрирования, является членом научных и ученых советов, редакций научных журналов, координатором научных программ.

Под руководством Р.А. Буянова и с его участием разработана теория кристаллизации малорастворимых гидроксидов по механизму ориентированного наращивания и развита теория образования и эволюции их полиядерных гидроксокомплексов.

Развита фундаментальная теория магнитного действия катализаторов в низкотемпературной конверсии орто-водорода в пара-водород. Эти работы завершились созданием промышленного производства жидкого пара-водорода – ракетного топлива, на котором совершен полет космического корабля “Буран”.

Им с сотрудниками расшифрован “механизм карбидного цикла” в процессе каталитического разложения углеводородов с образованием углеродных нанонитей и волокон, разработана фундаментальная теория радикально-цепных неразветвленных реакций с участием гетерогенных катализаторов, проведен цикл исследований по механохимическим и термохимическим методам активации и повышению реакционной способности твердых реагентов в производстве катализаторов. Это позволило создать принципиально новые типы катализаторов высокоселективного гидрирования ацетиленовых и диеновых углеводородов и др.

Р.А. Буянов дал определение и очертил границы области науки, получившей название “Научные основы приготовления и технологии катализаторов”. Разработана научная классификация всех возможных причин дезактивации катализаторов.

В 60-70-х годах в содружестве с головным Институтом мономеров синтетического каучука (Ярославль) разработаны и внедрены в промышленность катализаторы для получения основных мономеров синтетического каучука (бутадиена, изопрена, стирола). На этих катализаторах вся промышленность СССР по производству синтетического каучука работала более 10 лет.

Под руководством Р.А. Буянова разработан и ряд других катализаторов и носителей, в том числе катализатор выделения серы по методу Клауса (лицензия продана французской фирме Рон-Пуленк и по ней во Франции построен цех), микросферический оксид алюминия для катализатора производства хлорвинила и др.

Р.А. Буянов – автор более 600 научных работ, монографий, обзоров, патентов. Под его руководством организованы и регулярно проводятся, начиная с 1983 г., Российские конференции по научным основам приготовления и дезактивации катализаторов.

Р.А. Буянов является главой школы в области научных основ приготовления катализаторов, в числе его учеников 6 докторов и 23 кандидата наук, успешно работающих в науке и промышленности. В настоящее время Роман Алексеевич активно участвует в выполнении ряда научных проектов, связанных с созданием новых технологий.

Научный совет по катализу ОХНМ РАН и редакция Каталитического бюллетеня сердечно поздравляют Романа Алексеевича с юбилеем, желают ему крепкого здоровья и новых творческих успехов!

|

Российская академия наук Oтделение химии и наук о материалах НАУЧНЫЙ СОВЕТ ПО КАТАЛИЗУ |

Секретариат Научного совета по катализу ОХНМ РАН (НСК) предлагает Вашему вниманию сводный отчет о деятельности Совета и научных исследованиях в области катализа, выполненных научными коллективами под руководством членов Научного совета по катализу.

Отчет состоит из трех разделов:

Тексты отчетов, полученные от членов НСК и научно-исследовательских коллективов, практически не подвергнуты корректировке.

В 2016 году в рамках научно-организационной деятельности Научного совета по катализу ОХНМ РАН (НСК) были выполнены следующие мероприятия.

Изданы материалы проведенных конференций.

Секретариат НСК ведет переписку и текущую работу с членами Научного совета по катализу ОХНМ РАН.

Продолжается сотрудничество с организациями Академий наук РФ и стран СНГ, Министерствами РФ, институтами разных ведомств и другими организациями России, дальнего и ближнего зарубежья по различным вопросам научной, научно-организационной, учебно-преподавательской и общественной деятельности в области катализа.

Фундаментальные исследования в области создания новых каталитических систем

и применения физических методов для их диагностики

Исследование механизма конверсии ДМЭ в низшие олефины

Методами высокотемпературной ИК спектроскопии диффузного отражения in situ (ИКДО) в сочетании с квантово-химическим моделированием показано, что в процессе формирования активных центров превращения ДМЭ на поверхности цеолитных катализаторов на основе ZSM-5 принимают участие различные по силе кислотные центры Бренстеда (БКЦ). Слабые БКЦ участвуют в метоксилировании поверхности, сильные БКЦ протонируют ДМЭ. Взаимодействие метокси-группы с протонированным ДМЭ приводит к образованию кетена и формированию карбкатиона СН3+, который, атакуя ДМЭ, создает первую С–С связь через интермедиаты: карбониевые катионы и илидные частицы. Таким образом, образование олефинов при температурах 300–350°C происходит по карбоний-илидному механизму. Все типы БКЦ, интермедиаты и продукты (олефины и алканы) идентифицированы на поверхности катализаторов методом ИКДО, их структура подтверждена квантово-химическими расчетами.

академик С.Н. Хаджиев, д.х.н. Н.В. Колесниченко, д.х.н. Г.Н. Бондаренко

Институт нефтехимического синтеза им. А.В. Топчиева РАН, г. Москва

Исследование каталитической активности синтезированных наноразмерных суспензий в синтезе Фишера-Тропша в условиях трехфазной системы газ-жидкость-твердое тело

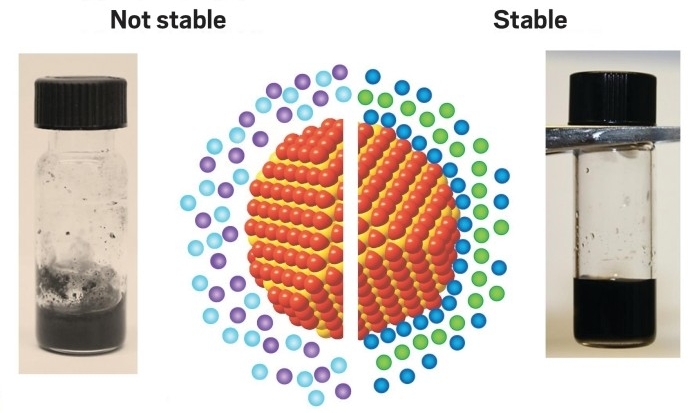

Показана возможность регулирования размера частиц дисперсной фазы Fe- и Со-катализаторов синтеза Фишера-Тропша путем варьирования таких параметров, как условия их приготовления, состав, природа и концентрация активной фазы и промотирующих добавок. Показано, что снижение размера части дисперсной фазы во всех случаях приводит к повышению производительности систем в отношении образования целевых продуктов синтеза. Оптимизация состава и условий приготовления контактов позволила увеличить производительность Со-катализаторов с 51 до 222 г/кг Со/ч, а железосодержащих суспензий – от 156 до 954 г/кг Fe/ч.

академик С.Н. Хаджиев, к.х.н. О.С. Дементьева

Институт

нефтехимического синтеза им. А.В. Топчиева РАН, г. Москва

Никель-кобальтовые катализаторы для кислородной и углекислотной конверсии метана в синтез-газ

Разработаны новые никель-кобальтовые нанесенные катализаторы для кислородной и углекислотной конверсии метана в синтез-газ, при 800-920°C показавшие конверсию метана 94-98%, выходы СО и Н2 91-98%, что является результатами, соответствующими мировому уровню. Сущность разработки – использование в качестве носителя для приговления катализатора цеолита структуры MFI, синтезированного ускоренным методом гидротермально-микроволнового синтеза. Использование данного носителя и оптимального сочетания активных компонентов позволяет предотвратить закоксовывание катализаторов. Катализаторы предполагается использовать для реализации инновационных процессов получения синтез-газа кислородной и углекислотной конверсией метана.

академик А.Г. Дедов, академик И.И. Моисеев, д.х.н., проф.

А.С. Локтев, аспирант И.Е. Мухин

Российский государственный университет нефти и газа им. И.М. Губкина, г. Москва

Катализаторы для конверсии пропан-бутановой фракции, изобутанола и гидроконверсии рапсового масла

Разработаны новые катализаторы для конверсии пропан-бутановой фракции, изобутанола и гидроконверсии рапсового масла, позволяющие получать ценные продукты нефтехимии – ароматические углеводороды или олефины С2-С4 c выходом более 50%. Сущность и новизна разработки – использование для приготовления катализаторов цеолитов структуры MFI и микромезопористых материалов, полученных ускоренным методом гидротермально-микроволнового синтеза. Микроволновое воздействие позволяет сократить продолжительность синтеза цеолитов и микромезопористых материалов, повысить их степени кристалличности. Значимость разработки обусловлена тем, что катализаторы, получаемые из синтезированных микроволновым методом цеолитов и микромезопористых материалов, превосходят аналоги, полученные традиционным гидротермальным методом.

академик

А.Г. Дедов, академик И.И. Моисеев, д.х.н., проф.

А.С. Локтев, к.х.н. Д.А. Левченко,

аспиранты А.А. Караваев, Е.А. Исаева

Российский государственный университет нефти и

газа им. И.М. Губкина, г. Москва

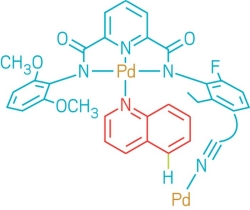

Полимер-иммобилизованные катализаторы смешанного типа для селективного гидрирования алкеновых и ацетиленовых соединений

Разработаны два подхода к синтезу моно- и биметаллических полимер-иммобилизованных катализаторов смешанного типа на основе Pd, Pd-Cu, Pd-Ag, закрепленных на поверхности неорганических носителей (SiO2 Al2O3, ZnO): модификация поверхности неорганического носителя ZnO полиэтиленгликолем или пектином и последующее закрепление комплексов палладия; фронтальная полимеризация металлосодержащего мономера в присутствии неорганического носителя. Показано, что получаемые органо-неорганические гибридные нанокомпозиты являются селективными катализаторами в реакции гидрирования алкеновых и ацетиленовых соединений. Модификация полимером способствует формированию высокодисперсных частиц активной фазы (2-4 нм) и их стабилизации; не происходит субстратной изомеризации при гидрировании аллилового спирта; обеспечивается селективное гидрирование ацетиленовых спиртов в олефиновые (полупродукты синтеза витаминов А, Е, К) и удаление ацетиленовых примесей при синтезе мономеров винильного типа из нефтяного сырья(ацетиленовых соединений из этилена, пропилена и др., ингибирующих их каталитическую полимеризацию).

академик

С.М. Алдошин, Н.Д. Голубева, Г.И. Джардималиева

Институт проблем химической физики РАН, г. Черноголовка

Фотокаталитическая технология очистки воздуха от паров фторированных анестетиков и других галогенсодержащих летучих загрязнителей в медицине

Совместно с Московским областным научно-исследовательским институтом акушерства и гинекологии изучена возможность применения фотокатализа для очистки воздуха от примеси севофлурана (CF3)2-CH-O-CH2F) – препарата для общей анестезии. Методами масс-спектрального и химического анализов установлено, что продуктами фотокаталитического окисления севофлурана в воздухе являются углекислый газ и фторид водорода. Показано, что выделяющийся в результате реакции HF может быть полностью связан химическим поглотителем из гранулированного карбоната кальция, установленным на выходе фотокаталитической ячейки. На основании полученных результатов предложена рабочая схема опытного устройства для очистки воздуха от паров севофлурана и других галогенсодержащих органических загрязнителей.

академик

С.М. Алдошин, И.Л. Балихин, В.И. Берестенко, И.А. Домашнев,

Е.Н. Кабачков, Е.Н. Куркин, В.Н. Троицкий, В.М.

Мартыненко, Е.Ю. Упрямова

Институт проблем химической физики РАН, г. Черноголовка

Катализаторы селективного гидрирования фенилацетилена на основе никеля, нанесенного на наноалмаз

С целью оптимизации состава активного центра катализатора селективного гидрирования в данной работе с использованием синхротронного рентгеновского излучения методами термопрограммированного восстановления in situ и EXAFS исследованы никелевые катализаторы, нанесенные на наноалмаз (ND), полученный методом детонационного синтеза. Проведено сравнение с данными для соединений, моделирующих возможные состояние никеля в активном центре. Использование для обработки данных EXAFS малораспространенного метода вейвлет-преобразования вместо общепринятого Фурье-преобразования позволило получить 3D-изображения, представляющие зависимость EXAFS-функции от расстояния до центрального атома и значений волнового вектора, и выявить два типа связывания никеля с поверхностью наноалмаза (через кислородсодержащие функциональные группы или непосредственно с углеродом поверхности). Показана возможность регулирования селективности нанесенного на ND никеля путем удаления одного из двух типов активных центров, прогреванием в аргоне при 900°С или окислением на воздухе при 300°С. Полученные фундаментальные данные позволили эффективно регулировать селективность катализаторов в гидрировании фенилацетилена.

д.х.н.

Е.С. Локтева, к.х.н. Е.В. Голубина, к.х.н. Я.В. Зубавичус и др.

Московский государственный университет имени М.В. Ломоносова,

Химический факультет, г. Москва

НИЦ Курчатовский институт, г.

Москва

Жидкофазное эпоксидирование пропилена и циклогексена с использованием органокатализатора

Методами УФ-, ИК- и ЯМР-спектроскопии подтверждена структура синтезированного органокатализатора, который представляет собой трифторацетофенон, ковалентно иммобилизованный на поверхности силиката SBA-15; оценена частота оборотов реакции (TOF) жидкофазного эпоксидирования пропилена и циклогексена, значительно превышающая соответствующие величины, полученные на других каталитических системах.

Установлена зависимость скорости жидкофазного эпоксидирования гексена пероксидом водорода на двух образцах титаносиликата, различающихся на два порядка размером частиц – 3 и 300 нм; в предположении протекания реакции на малых кристаллах в кинетической области определена степень диффузионного торможения на крупных кристаллах и проведена оценка величин эффективного коэфициента диффузии.

д.х.н.

Б.В. Романовский

Московский

государственный университет имени М.В. Ломоносова,

Химический факультет, г. Москва

Комплексообразование титана- и цирконадигидрофурановых металлациклов с алюминийорганическими соединениями и каталитическая активность образующихся комплексов в полимеризации ε-капролактона

Взаимодействием

титанадигидрофурановых и цирконадигидрофуранового металлациклов

Cp2Ti[η2-C(SiMe3)=C(Ph)–CR1(R2)O]

(где R1

= R2

= Me

(1) и R1

= H,

R2

= Ph)

и Cp2Zr[η2-C(SiMe3)=C(SiMe3)–С(Me)2O]

с iBu2AlH

синтезированы цвиттерионные 1:1 комплексы, содержащие мостик Al‐H–M (M= Ti,

Zr)

наряду с координационной связью Al–O.

В противоположность этому, реакция 1

с EtAlCl2

приводит к образованию 1:1 аддукта, содержащего только

координационную Al–O-связь.

По данным РСА, в результате комплексообразования с кислотой Льюиса

происходит сильное удлинение связей M–C(SiMe3)

и/или M–O

металлацикла, вследствие чего все полученные цвиттерионы оказваются

способными катализировать полимеризацию

ε-капролактона(ε-КЛ) с раскрытием цикла. Наиболее активен в полимеризации цвиттерионный

титановый комплекс, полученный из металлацикла 1. В этом случае

процесс полимеризации протекает уже при комнатной температуре, давая

через сутки поли-ε-КЛ

с выходом 72% и молекулярной массой 168000 (Mw/Mn

= 1.81). А если температуру повысить до 75°C, то уже через

один час молекулярная масса полимера достигает 195000 (Mw/Mn

= 2.14) при выходе 63%.

д.х.н.

В.Б. Шур, В.В. Бурлаков, В.С. Богданов, О.О. Соколова, П.

Арндт, А. Шпанненберг, М.Х. Миначева, К.А. Лысенко, И.А. Ананьев,

У. Розенталь

Институт элементоорганических соединений им. А.Н. Несмеянова РАН, г.

Москва

Институт

катализа им. Лейбница при Университете Ростока, г. Росток, Германия

Изучение морфологии катализатора, образующегося в вакууме на поверхности графита при высокотемпературном разложении HAuCl4 и Ni(NO3)2

Впервые на уровне единичных наночастиц выявлена морфология катализатора, образующегося в вакууме на поверхности графита при высокотемпературном разложении HAuCl4 и Ni(NO3)2, и определены функции его компонентов. Установлено, что катализатор состоит из смеси наночастиц золота и окисленного никеля. Каталитические свойства золото-никелевого покрытия определены по отношению к кислороду и водороду. При температуре 300°C на наночастицах в результате последовательной выдержки в Н2, а затем в О2 (двухэтапного процесса) образуются вода и ОН-группы, в то время как для катализатора, состоящего из наночастиц золота, синтез воды возможен только в результате последовательной экспозиции в Н2, затем в О2 и снова в Н2 (трехэтапного процесса). Показано, что наблюдаемые эффекты интерпретируются в рамках модели, предполагающей существование нескольких форм адсорбции водорода с существенно разной энергией связи. Сильно связанный водород локализован на золотых наночастицах и/или на интерфейсе золото-графит; водород, имеющий достаточно низкий барьер поверхностной миграции и способный к реакции с кислородом, адсорбирован на наночастицах окисленного никеля или на их интерфейсе с золотом. На покрытии, сформированном только из золотых наночастиц, слабо связанный водород, образовавшийся при первой экспозиции в H2, не сохраняется в достаточной концентрации к моменту начала экспозиции в кислороде, но вновь получается в достаточном количестве на третьей стадии эксперимента при повторной экспозиции образца в водороде.

д.х.н.

Б.Р. Шуб

Институт химической физики им. Н.Н. Семенова РАН, г. Москва

Оксидная система Na2WO4-MnxOy/SiO2 как катализатор окислительной конденсации метана

Оксидная система Na2WO4-MnxOy/SiO2 является перспективным катализатором процесса окислительной конденсации метана (ОКМ). Ранее было показано, что для данной каталитической системы кинетика образования продуктов ОКМ (этана и этилена) может быть описана в рамках модели Марса-ван-Кревелена, предполагающей попеременное (циклическое) восстановление и реокисление активных центров катализатора. Также было установлено, что смешанный оксид Na2WO4-MnxOy/SiO2 содержит две формы реакционноспособного кислорода. Первая является “сильно связанной” и может быть обратимо удалена при восстановлении катализатора в токе водорода и метана при температурах выше 600°C. Вторая – более слабо связанная; она обратимо удаляется из образца в режиме термопрограммированной десорбции при температурах выше 650°C.

Методом дифференциальной сканирующей калориметрии были экспериментально определены величины энергии связи решеточного кислорода в смешанном оксиде Na2WO4-MnxOy/SiO2. Установлено, что для “слабосвязанной” формы кислорода (содержание в системе около 56 мкмоль/г) она составляет ~337 кДж/моль. Эта величина указывает на то, что термодесорбция кислорода обусловлена переходом Mn(4+) → Mn(3+). Именно эта форма вносит наиболее существенный вклад в суммарную скорость стационарной каталитической реакции ОКМ. Количество (~ 443 мкмоль/г) и энергия связи кислорода более прочно связанного с оксидной решеткой типа (420-435 кДж/моль) указывают на то, что он ассоциирован с присутствующим в образце вольфрамом; однако на основании полученных данных сделать вывод о том, каким именно переходам и изменениям структуры отвечают удаление и присоединение кислорода в этой форме, не представляется возможным без проведения дополнительных исследований с привлечением структурно-чувствительных физических методов. С уверенностью, однако, можно констатировать, что величина энергии связи для этой формы кислорода столь велика, что в условиях стационарного катализа (т.е. в присутствии O2 в газовой фазе даже в небольших концентрациях) степень его вовлечения в каталитический процесс ОКМ не может быть существенной.

д.х.н.

М.Ю. Синев

Институт химической физики им. Н.Н. Семенова РАН,

г. Москва

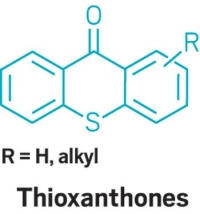

Исследование селективного фотокаталитического окисления ароматических аминов

Открытая ранее реакция селективного фотокаталитического окисления ароматических аминов до п-аминофенолов синглетным кислородом была успешно распространена в 2016 году на соответствующие субстраты нафталинового и антраценового рядов. п-Аминонафтолы образуются, как и аминофенолы, с селективностью более 90%, характеристики процесса окисления 1-аминоантрацена устанавливаются. Получены данные по влиянию структуры фталоцианинового фотосенсибилизатора (природы центрального атома металла и заместителей) и его концентрации в растворе или на поверхности носителя на характеристики процесса окисления. Показано критическое значение содержания воды в реакционной среде – в отсутствие воды реакция не протекает. На основе этих и других изученных закономерностей предложены стехиометрия и схема механизма реакции, не противоречащая экспериментальным наблюдениям.

д.х.н. О.Л. Калия, к.х.н. Т.М. Федорова

Государственный научный центр “НИОПИК”, г. Москва

Катализаторы для процесса селективной гидроочистки бензинов каталитического крекинга

Продолжаются исследования и разработки триметаллических сульфидных катализаторов состава KNiWS и KCoMoS, в том числе с пониженным содержанием металлов, для процесса селективной гидроочистки бензинов каталитического крекинга с сохранением октанового числа. Показано, что щелочной металл изменяет не только свойства, но и концентрацию обоих типов (ГДС и ГИДО) активных центров KCoMoS2 или KNiWS2 частиц по схожему механизму. Установлено, что химические свойства бензина каталитического крекинга обуславливают состав используемой композиции: для сырья с высоким содержанием серы оптимальными являются NiWS системы, в то время как для сырья с низким количеством серы и высокой концентрацией олефинов подходят системы KCoMoS.

д.х.н.

П.А. Никульшин, к.х.н. А.В. Можаев, к.х.н. Д.И. Ишутенко, асп.

Ю.В. Анашкин, д.х.н. А.А. Пимерзин

Самарский государственный технический университет, г. Самара

Разработка фундаментальных основ аддитивной технологии переработки биомассы с целью получения ценных химических соединений и топливных компонентов

Разработаны методики синтеза наночастиц магнетита в порах сверхсшитого полистирола (СПС) марок MN270 (без функциональных групп), MN100 (функционализированный аминогруппами) и MN500 (функционализированный сульфогруппами). Установлена термостабильность СПС различных марок. Стабильные матрицы СПС MN270 и MN100 были использованы в дальнейшем для синтеза магнитных наночастиц оксида железа и Ru-содержащих магнитноотделяемых катализаторов. Определены оптимальные условия внедрения (метод импрегнации) прекурсора, его природа (железа (III) нитрат), его оптимальная концентрация (200 г/л в этаноле) и температура разложения (300 °С). Методами ПЭМ исследованы параметры частиц магнетита, образованных в порах СПС в результате термического разложения нитрата железа. Данные просвечивающей электронной микроскопии показали, что размер наночастиц оксида железа составляет 3,6±0,5 нм и не зависит от типа исходного СПС. Структура окиси железа была определена с помощью метода дифракции рентгеновских лучей.

Исследованы магнитные свойства синтезированных Ru-содержащих магнитноотделяемых катализаторов. Методом РФЭС определён состав их поверхности. Было обнаружено, что в ходе синтеза наночастиц оксида железа образуются исключительно магнетитовые наночастицы. ИК-спектроскопическое исследование показало, что условия восстановления катализаторов не оказывают влияния на полимерную матрицу СПС, а адсорбция глюкозы (субстрата) и сорбита (продукта реакции гидрирования) на катализаторах незначительна.

Проведено тестирование синтезированных Ru-содержащих магнитноотделяемых катализаторов в реакции гидрирования глюкозы до сорбита. Определены оптимальные условия реакции (температура, парциальное давление водорода, концентрации субстрата и катализатора, интенсивность перемешивания) и стабильность катализаторов в нескольких циклах использования. Наиболее эффективными оказались образцы катализаторов на основе СПС марки MN100, приготовленные с использованием в качестве прекурсора рутения (IV) гидроксотрихлорида. Стабильность всех образцов синтезированных катализаторов в гидротермальных условиях процесса гидрирования глюкозы была подтверждена трехкратным использованием без заметного снижения их активности.

д.х.н.,

проф. Э.М. Сульман

Тверской

государственный технический университет, Институт нано- и биотехнологий, г. Тверь

Эффективный нанокатализатор для окислительной функционализации ароматических углеводородов

Разработан новый эффективный гетерогенный нанокатализатор окислительной функционализации ароматических углеводородов на основе NiIII-комплексов, допированных в силикатные наночастицы ([(bpy)xNiIII]@SiO2. Преимущества этого нанокатализатора по сравнению с известными гомогенными молекулярными никелевыми и палладиевыми катализаторами заключаются в высокой активности, количественных выходах продуктов фторалкилирования, десятикратном снижении рабочей концентрации катализатора (менее 1%), стабильности во времени и легкой регенерации.

д.х.н.Ю.Г. Будникова,

д.х.н. А.Р. Мустафина, к.х.н. М.Н. Хризанфоров,

к.х.н. С.В. Федоренко, асп. С.О. Стрекалова, к.х.н. К.В. Холин,

М.Е. Жилкин

Институт органической и физической химии им. А.Е. Арбузова КазНЦ РАН, г. Казань

Контроль скорости разложения фосфорорганических ингибиторов ацетилхолинэстеразы с помощью биомиметических катализаторов

Предложены новые биомиметические катализаторы (пиримидинсодержащие и фосфониевые ПАВ), позволяющие контролировать скорость разложения фосфорорганических ингибиторов ацетилхолинэстеразы (от ускорения до аномального ингибирования), проявляющие высокую эффективность в низких концентрациях и выраженную субстратную специфичность.

академик

О.Г. Синяшин, д.х.н., проф. Л.Я. Захарова, проф. В.С. Резник,

д.х.н. В.Э. Семенов,

к.х.н. Д.Р. Габдрахманов, к.х.н. Г.А.

Гайнанова, к.х.н. Ф.Г. Валеева, асп. Д.А. Самаркина

Институт

органической и физической химии им. А.Е. Арбузова КазНЦ РАН, г.

Казань

Конформационый анализ заряженных бис хелатных комплексов Ni(II)

Решена задача полного конформационного анализа заряженных бис хелатных комплексов Ni(II) на основе P,N-содержащих гетероциклических лигандов (1,5-диаза-3,7-дифосфациклооктанов) – наиболее активных никелевых катализаторов электрохимического получения водорода. Обнаружены корреляции структурно-динамических параметров этих комплексов с их каталитической активностью. Максимальной активности катализатора соответствует высокая конформационная лабильность как гетероциклического фрагмента, так и геометрии центрального иона, реализующихся со стерически незагруженными заместителями на фосфоре и ароматическими группами на азоте.

академик

О.Г. Синяшин, д.х.н., проф. А.А. Карасик, д.х.н. Ш.К. Латыпов,

А.Г. Стрельник, к.х.н. А.С. Балуева, Ю.С. Спиридонова

Институт органической и физической химии

им. А.Е. Арбузова КазНЦ РАН, г. Казань

Региоселективное амидирование бинора-S органическими нитрилами в присутствии воды, катализированное FeCl3·6H2O

Впервые осуществлено однореакторное амидирование бинора-S органическими нитрилами (ацетонитрил, пропионитрил, валеронитрил, бензонитрил) под действием FeCl3·6H2O в условиях: 150°C, 6 ч. Реакция проходит нетривиально путем региоизбирательного разрыва связи С4-С5 циклопропанового кольца бинора-S с образованием соответствующих N-замещенных амидов с выходами 70-90%. Омылением амидов синтезирован 10-амино-гексацикло[12.1.0.0.2,60.3,80.5,709,13]тетрадекан (аналог известного противовирусного препарата 1-аминоадамантана – мидантана), представляющий практический интерес для производства ноотропных и противовирусных препаратов.

проф.

Р.И. Хуснутдинов, к.х.н. Т.М. Егорова

Институт

нефтехимии и катализа РАН, г. Уфа

Короткий и эффективный путь стереоселективного каталитического синтеза природного лембехина В – индуктора раннего апоптоза в клетках лейкемии

Разработан эффективный путь стереоселективного синтеза лембехина B с применением на ключевой стадии новой реакции Ti-катализируемого кросс-цикломагнирования О-содержащих и алифатических 1,2-диенов с помощью реактивов Гриньяра. В результате реакции цикломагнирования 1,2-нонадекадиена и тетрагидропиранового эфира 13,14-пентадекадиенола с помощью EtMgBr в присутствии металлического Mg и катализатора Cp2TiCl2 (10 мол %) в условиях: 20-22°C, 7 ч, Et2O, после гидролиза реакционной массы получен тетрагидропирановый эфир (13Z,17Z)-тетраконта-13,17-диенола с выходом 88%. В результате последовательных трансформаций синтезированного эфира получен целевой лембехин В.

С целью изучения закономерностей влияния структуры лембехина на проявляемую им биологическую активность с применением разработанного подхода удалось синтезировать линейку рацемических и природных лембехинов В, в том числе длинно- (С36-С40) и короткоцепочечных (С25-С34) аналогов. С привлечением проточной цитофлуорометрии впервые показано, что лембехин B является селективным индуктором раннего апоптоза клеточных культур лейкемии Jurkat, HL-60 и K562. В настоящее время проводятся интенсивные исследования в данном направлении с целью реализации стереоселективных методов синтеза всей линейки природных лембехинов и их аналогов, в том числе для проведения полномасштабных фармакологических исследований по изучению биологической активности и выявления закономерностей структура – противоопухолевая активность.

чл.-корр.

РАН У.М. Джемилев, д.х.н. В.А. Дьяконов,

к.х.н. А.А. Макаров,

д.м.н. Л.У. Джемилева

Институт нефтехимии и катализа РАН, г. Уфа

Ti-Катализируемое кросс-цикломагнирование 1,2-диенов в стереоселективном синтезе практически важных феромонов насекомых-вредителей

В продолжение исследований по изучению областей приложения разработанных в лаборатории новых фундаментальных реакций каталитического циклометаллирования непредельных соединений впервые показано, что реакции каталитического цикломагнирования 1,2-диенов являются удобным инструментом для стереоселективного построения соединений, содержащих в своей структуре 1Z,5Z-диеновые фрагменты, и могут быть с успехом использованы при разработке препаративных методов синтеза феромонов насекомых. Так, с применением на ключевой стадии синтеза кросс-цикломагнирования алифатических 1,2-диенов с O-содержащими алленами, взятых в соотношении 1.2:1, в условиях (Et2O, 20-22°C, 4 ч) разработаны стереоселективные методы получения гексадека-7Z,11Z-диен-1-аля – компонента феромонов минирующей моли цитрусовых растений Phyllocnis tiscitrella, гексадека-7Z,11Z-диен-1-ил ацетата – аттрактанта розового коробочного червя хлопчатника Pectinophora gossypiella, пентакоза-7Z,11Z-диен и нонакоза-7Z,11Z-диена – аттрактантов плодовой мухи Drosophila melanogaster с высокими выходами (60-75%), представляющих исключительный интерес для сельского хозяйства для борьбы с вредителями сельскохозяйственных и декоративных растений.

чл.-корр.

РАН У.М. Джемилев, д.х.н. В.А. Дьяконов,

к.х.н. И.И. Исламов,

к.х.н. А.А. Макаров

Институт нефтехимии и катализа РАН, г. Уфа

Гетерогенно-каталитические способы синтеза практически важных пиридинов

Соединения с пиридиновым фрагментом играют ключевую роль в некоторых биологических процессах, наиболее важные из них – окислительно-восстановительные процессы с участием кофермента никотинамидадениндинуклеотида (NADP). На основе пиридина и алкилпиридинов синтезируют важные фармацевтические препараты, сельскохозяйственные химикаты, латексы, экстрагенты, ингибиторы коррозии металлов, растворители, поверхностно-активные вещества, ускорители вулканизации каучука и многое другое.

С целью разработки селективных гетерогенно-каталитических способов

синтеза практически важных N-гетероциклических соединений впервые

изучены каталитические свойства в синтезе пиридина и его

алкилпроизводных реакцией этанола с формальдегидом и аммиаком новых

каталитических систем, приготовленных на основе цеолитов Y

и MOR с комбинированной микро-мезо-макропористой структурой (Y

-ммм и MORммм) и аморфных мезопористых алюмосиликатов

(ASM) с различным мольным соотношением Si/Al = 40

и 80, отличающихся текстурой и кислотными свойствами. Установлена

высокая активность в указанной выше реакции каталитических систем на

основе цеолита H-Yммм и алюмосиликатов

д.х.н.

Б.И. Кутепов, д.х.н. Н.Г. Григорьева, к.х.н. Р.Р. Талипова,

к.х.н. М.Р. Аглиуллин,

к.х.н. С.В. Бубеннов, асп. Н.А. Филиппова,

асп. А.М. Гатаулин

Институт нефтехимии и катализа РАН, г. Уфа

Синтез новых полициклических молекул, имеющих девять конденсированных циклов в составе своей структуры “лестничного” типа

Разработан удобный способ синтеза новых полициклических молекул, имеющих девять конденсированных циклов в составе своей структуры “лестничного” типа и содержащих систему 5,11-дигидроиндоло[3,2-b]карбазола в качестве базового остова. Показана возможность модификации каркаса полученных конденсированных производных. Предложенный способ синтеза конденсированных производных 5,11-дигидроиндоло[3,2-b]карбазола основан на последовательности реакций ацилирования по Фриделю-Крафтсу и Pd-катализируемой С-Н активации, исходя из доступных соединений – 5,11-диалкил-6,12-ди(гетеро)арилзамещенных индоло[3,2-b]карбазолов. Впервые была показана возможность металл-катализируемой активации С-Н связи в молекулах 5,11-дигидроиндоло[3,2-b]карбазолов.

академик

В.Н. Чарушин, к.х.н. Г.Л. Русинов, к.х.н. Р.А. Иргашев, Н.А. Казин, Г.А. Ким

Институт органического синтеза им. И.Я. Постовского УрОРАН, г. Екатеринбург

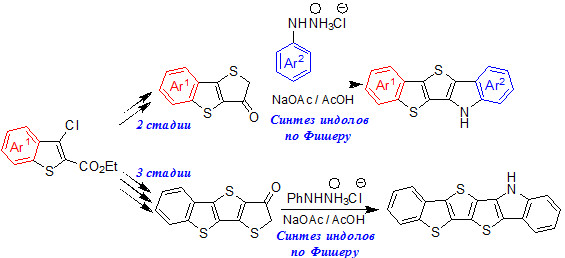

Синтез нового класса несимметричных гетероаценов

Разработан эффективный способ получения производных 6H-бензо[4',5']тиено-[2',3':4,5]тиено[3,2-b]индола, нового класса несимметричных гетероаценов, а также их гексациклических аналогов, с использованием реакции индолизации по Фишеру в качестве ключевой стадии.

академик В.Н. Чарушин, к.х.н. Г.Л. Русинов, к.х.н. Р.А. Иргашев, А.А. Кармацкий, Г.А. Ким

Институт органического синтеза им. И.Я. Постовского УрОРАН, г. Екатеринбург

Исследование влияния цеолитной матрицы β-цеолита (модуль, кислотность, содержание цеолита, платины) на показатели реакции изомеризации н-гептана (выход суммы изомеров, выход ди- и триметилзамещенных изомеров гептана)

Приготовлены и исследованы в реакции изомеризации н-гептана Pt/BEA/Al2O3 катализаторы с варьированием содержания в катализаторе цеолита и платины, нанесенной из двух типов предшественников – гексахлорплатиновой кислоты и аммиаката платины. Установлено, что оптимальными катализаторами являются системы с 0,2-0,3 % мас. платины, нанесенной из водного раствора H2PtCl6, демонстрирующие близкий к равновесному выход метилциклопентана, а также высокие выходы изомеров гептанов при минимальном вкладе побочных реакций гидрокрекинга алканов. Катализаторы могут быть использованы в процессе гидроизомеризации С7-углеводородов в прямогонных бензиновых фракциях и в бензинах каталитического риформинга для улучшения их экологических характеристик.

д.х.н., проф. А.С. Белый, к.х.н. М.Д. Смоликов

Институт проблем переработки углеводородов СО РАН, г. Омск

Исследование этенолиза алкенов C5+ как метода синтеза пропилена

Изучена возможность синтезапропилена из смеси алкенов С5+иэтилена на катализаторах метатезиса, обладающих кислотной функцией. Посредством термодинамических расчетов показано, что превращение алкена С5+ в смеси с этиленом позволяет получать пропилен с высоким выходом (до 60% для пентена-1 при стехиометрическом соотношении с этиленом). Селективность процесса по пропилену при сверхстехиометрическом количестве этилена в сырьевой смеси может превышать 90%. По результатам испытаний установлено, что на катализаторе Re/ВA обеспечивается высокая селективность процесса (85-90% по пропилену), тогда как процесс на Re/SZA осложняется протеканием побочных реакций олигомеризации и метатезиса. Результаты могут быть использованы при создании новых технологий переработки газового сырья с получением продуктов для нефтехимии.

к.х.н. А.В. Лавренов, к.х.н. Е.А. Булучевский

Институт проблем переработки углеводородов СО РАН, г. Омск

Исследование влияния компонентного состава цеолитсодержащего катализатора на совместные превращения растительных масел с вакуумными газойлями различного группового состава

Исследовано влияние компонентного состава цеолитсодержащего катализатора на совместные превращения растительных масел с вакуумными газойлями различного группового состава. Определено, что при высоком содержании цеолита Y в составе катализатора (20,0 мас. %) выходы целевых продуктов крекинга смесевого сырья существенно не зависят от жирнокислотного состава растительного масла, входящего в его состав. Влияние типа масла проявляется только при повышении содержания в составе активного компонента катализатора цеолита ZSM-5. Показано, что многокомпонентная активная матрица (аморфный алюмосиликат + оксид алюминия + монтмориллонит) обеспечивает протекание первичного крекинга, способствует достижению высокой конверсии смесевого сырья и повышенному выходу бензиновой фракции. Кроме того, вышеуказанная матрица обеспечивает повышенное образование кокса, что имеет большое значение для замыкания теплового баланса при превращении глубоко гидроочищенных вакуумных газойлей. Результаты важны для разработки технологий переработки растительной биомассы в компоненты моторных топлив.

к.т.н. В.П. Доронин, к.х.н. П.В. Липин

Институт проблем переработки углеводородов СО РАН, г. Омск

Катализатор ароматизации газообразных углеводородов

Для процесса ароматизации низших алканов синтезированы элементоалюмосиликаты (Э-АС) структурного типа цеолита ZSM-5, содержащие в своем составе наряду с атомами кремния и алюминия атомы Ga, In, Zn и Zr. На основании данных структурно-морфологических исследований полученных образцов установлено, что введение металлов в цеолитную структуру приводит к образованию различных по морфологии и элементному составу частиц.

Исследования электронного состояния активных центров Э-АС показали, что катионы Ga и Zn связаны с ионами кислорода в каналах цеолита с энергиями связи, характерными для оксидов этих элементов. Высокое значение энергии связи Zn3d (1023.0 эВ) объясняет стабильность ионов цинка в структуре Zn-AC во время реакции. Изоморфное замещение ионов Si4+ в кристаллической решетке цеолита на ионы Zr4+ и In3+, несмотря на относительно низкие значения энергии связи Zr3d (183.4 эВ) и In3d (446.3 эВ), также обуславливает стабильность систем Zr-АС и In-AC. Лишь при сильном нагреве после разрушения канальной структуры цеолита наблюдается агрегирование Zr и In в оксидные кластеры. Полученные Э-АС проявляют высокую активность и селективность в процессе превращения пропана в ароматические углеводороды (АрУ), а наиболее эффективным является катализатор с добавкой галлия: селективность образования на нем целевого продукта превышает 52% при конверсии пропана 97%. Катализатор может использоваться для переработки попутных нефтяных и отходящих нефтезаводских газов в практически важные продукты.

д.х.н.

А.В. Восмериков

Институт химии нефти СО РАН, г. Томск

Применение автоклавных технологий для растворения оксидных матриц катализаторов; разработка катализаторов для изомеризации н-алканов

С целью разработки методики оперативного контроля структурно-химических изменений катализаторов нефтепереработки в процессе эксплуатации проводилась оценка эффективности применения автоклавных технологий для растворения оксидных матриц катализаторов и вскрытия различных соединений, химических фаз цветных и благородных металлов, входящих в состав катализаторов. Установлена эффективность данного метода при селективном выделении отдельных исследуемых фаз для повышения точности методов рентгеновской дифрактометрии. Предложена методика оценки размеров частиц платины в образцах катализатора риформинга, в том числе отработанного.

Проводятся исследования по разработке новых катализаторов для изомеризации н-алканов C4-C6 на основе диоксида циркония, модифицированного редкоземельными металлами, а также методов их синтеза путем легирования основной фазы анионными промоторами и катионами двух- и трехвалентных металлов (Y3+, Се3+, Sc3+, Fe3+, Mn2+, Са2+ и др.), стабилизирующими метастабильные модификации. Разработка нового семейства гетерогенных кислотных катализаторов на основе диоксида циркония является важным достижением науки в области катализа процессов нефтепереработки за последнее десятилетие, так как такие системы позволяют осуществлять изомеризацию н-парафинов при низкой температуре с высоким выходом высокоразветвленных изомеров.

д.т.н., проф. В.П. Твердохлебов

Сибирский Федеральный университет, Институт нефти и газа, г. Красноярск,

Институт химии и химической технологии СО РАН, г. Красноярск

Исследование механизма реакций Соногаширы и Хека с ангидридами ароматических кислот

Путем применения набора новых подходов, базирующихся на использовании феномена искусственной многомаршрутности, определены детали механизма элементарных стадий реакций сочетания Соногаширы и Хека с ангидридами ароматических кислот в качестве арилирующего реагента. В частности, установлена степени обратимости стадий с участием субстратов, а также быстрые и скорость определяющие стадии каталитических циклов.

В реакции Соногаширы результаты исследования зависимостей дифференциальной селективности реакций от различных параметров (отношения конкурирующих субстратов, природы и концентрации партнера по сочетанию) с одновременным анализом интегральных кинетических данных позволили установить, что арилгалогениды и арилацетилены участвуют в быстрых необратимых стадиях в присутствии палладиевых «безлигандных» каталитических систем. Скорость реакции определяется одной или комбинацией нескольких мономолекулярных стадий, в которых субстрат и партнер по сочетанию непосредственно не участвуют. Зависимость дифференциальной селективности по впервые обнаруженным полициклическим продуктам реакции Соногаширы указывает на участие основания в формировании катализатора, активного в образовании этих продуктов. Чувствительность дифференциальной селективности к природе предшественника катализатора согласуется с существованием нескольких (минимум двух) типов активных соединений, участвующих в образовании полициклических продуктов.

В реакции Хека с ароматическими ангидридами результаты исследования дифференциальной селективности в комбинации с гамметовскими корреляциями, полученных для конкурентных и неконкурентных вариантов реакции, а также результаты анализа интегральных кинетических данных расходования конкурирующих субстратов указывают на участие ангидрида и сочетающегося с ним алкена в быстрых необратимых стадиях каталитического цикла. Активность катализатора контролируется скоростью одной или нескольких мономолекулярных стадий каталитического цикла, в которых ангидрид и алкен непосредственно не участвуют.

д.х.н., проф. А.Ф. Шмидт

Иркутский государственный университет, г. Иркутск

Синтез катионных ацетилацетонатных комплексов палладия с анилиновыми лигандами

Впервые осуществлен синтез серии катионных ацетилацетонатных комплексов палладия с анилиновыми лигандами типа [(acac)Pd(L)2]BF4 (где L= NH2(p-Tol)2, NH2(о-Tol)2, NH2(2,6-Me2-Ph)2, NH2(2,6-i-Pr2-Ph)2). Методами РСА, ЯМР, ИКС и DFT-расчетов установлено образование водородной связи типа NH…FBF3 между анионом координированными анилиновыми и аминовыми лигандами, а также сохранение псевдокристаллической структуры в растворе. Обнаружено, что комплексы типа [(acac)Pd(L)2]BF4 (L= MeCN,NH2Ar) активны в индивидуальном виде, без добавок сокатализатора, в аддитивной полимеризации норборнена, димеризации стирола и его производных с селективностью до 90%. Предложен, экспериментально и теоретически обоснован механизм формирования постулируемых активных катионных гидридных комплексов палладия из прекурсора [Pd(acac)(MeCN)2]BF4 без участия сокатализатора на примере реакции димеризации стирола путем активации связи бор–фтор в анионе тетрафторбората, с последующей атакой образующегося трифторида бора κ2-O,O-ацетилацетонатного лиганда, связанного с палладием. Исследованы димеризация стирола и полимеризация норборнена в присутствии каталитических систем состава [(acac)Pd(L)2]BF4 и BF3·OEt2 (L= MeCN,NH2Ar,NHR2). Обнаружено, что в ряде случае данные каталитические проявляют высокую активность (до 5,5·106 гПНБ/{мольPd·ч}) в полимеризации норборнена, сопоставимую с лучшими представленными в научной литературе палладиевыми аналогами.

Получены новые конкурентоспособные каталитические системы для реакций полимеризации норборнена, 5-метоксикарбонилнорборнена, синтеза олигомеров норборнена с концевой винильной группой, сополимеризации норборнена с 5-метоксикарбонилнорборненом на основе систем состава {комплекс Ni(0)} /BF3OEt2, Ni(acac)2/PR3/AlEt3/HА/BF3·OEt2, [(acac)Pd(L)]BF4/BF3·OEt2, [(acac)Pd(L’)2]BF4/BF3·OEt2, [(acac)Pd(PPh3)(PR3)]BF4/BF3·OEt2, которые по активности сопоставимы с аналогами, представленными в патентной и научной литературе.

д.х.н., проф. Ф.К. Шмидт

Иркутский государственный университет, г. Иркутск

Теоретическое и экспериментальное изучение механизма катализа реакций нуклеофильного присоединения к ацетилену суперосновными системами MOH/DMSO

Методами квантовой химии и органического синтеза изучен механизм катализа нуклеофильного присоединения к ацетилену в суперосновных каталитических системах типа MOH/DMSO (М – щелочной металл). Развитие ранее предложенной модели катализа этими супероснованиями с участием недиссоциированных молекул КОН (NaOH) позволило идентифицировать первичные суперосновные каталитические комплексы, в которых молекулы DMSO входят в первую сольватационную сферу, и уточнить их последующее комплексообразование как с нуклеофилами, так и с ацетиленом. Показано, что первичные каталитические комплексы KOH•5DMSO и NaOH•4DMSO стабилизированы межлигандным взаимодействием. Результаты позволяют проводить оценку энергии активации реакций нуклеофильного присоединения воды, спиртов, сероводорода, тиолов и СН-кислот к тройной связи и качественно согласуются с экспериментом. Предложенная уточненная модель объясняет увеличение выхода продуктов этинилирования кетонов ацетиленом (нуклеофильное присоединение ацетиленид-иона к связи С=О) в присутствии небольших количеств воды, подавляющих енолизацию кетонов.

академик Б.А. Трофимов

Иркутский институт химии СО РАН им. А.Е. Фаворского СО РАН, г. Иркутск

проф. Н.М. Витковская, проф. В.Б. Кобычев, д.х.н. Е.Ю. Ларионова, В.Б. Орел

Иркутский государственный университет, г. Иркутск

Исследование процессов активации молекулярного водорода новыми перспективными каталитическими системами

Для гидрирования непредельных соединений в современной химической промышленности преимущественно используют катализаторы на основе переходных металлов. Стремление снизить стоимость катализаторов и их воздействие на окружающую среду определяет интерес к созданию новых каталитических систем для процессов гидрирования на основе более распространенных и безвредных элементов. В частности, среди систем на основе элементов главных групп значительный интерес представляют фрустрированные Льюисовские пары, для которых в последнее время продемонстрирована возможность их использования в процессах активации Н2 и гидрирования широкого круга непредельных соединений.

Показана возможность значительного усиления сигнала ЯМР за счет эффекта индуцированной параводородом поляризации ядер (ИППЯ) при активации параводорода с использованием ряда не содержащих атомов металла каталитических систем, представляющих собой фрустрированные Льюисовские пары анса-аминоборанов. Активация параводорода этими “молекулярными пинцетами” приводит к усилению сигналов в спектре ЯМР 1Н до 20 раз. Полученные результаты наглядно демонстрируют применимость метода ИППЯ для детального изучения механизма активации Н2 системами, не содержащими атомов металла. Все основные результаты получены впервые и являются существенным продвижением вперед в области развития методов значительного усиления сигнала ЯМР и применения этих методов для исследования механизмов важных каталитических процессов.

д.х.н. И.В. Коптюг

Международный томографический центр СО РАН,

г. Новосибирск

Полифункциональные нанороботы для синтеза наноразмерных алмазов

Открыто неизвестное ранее явление – физико-химический наноробот (ФХНР). Показано, что высокодисперсные частицы металлов подгруппы железа являются высокоактивными полифункциональными материалами (структурами), способными селективно выполнять ряд функций, инициировать протекание нескольких процессов разной природы и управлять ими в определенной последовательности технологических стадий. Такие полифункциональные наноразмерные структуры, выступающие в роли физико-химических нанороботов, управляют многостадийной технологией. Явление ФХНР впервые было обнаружено нами на примере синтеза углеродных наноструктур при разложении углеводородов на Ni-частицах по расшифрованному нами механизму карбидного цикла.

Разработан способ управления ФХНР с целью получения различных продуктов (материалов). В частности, предложен способ синтеза наноразмерных алмазов из углеводородов при атмосферном давлении и температуре ниже 700°C и другие синтезы.

чл.-корр. РАН Р.А. Буянов, академик В.Н. Пармон,

чл.-корр. РАН З.Р. Исмагилов, д.х.н. О.Ю. ПОдъячева

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

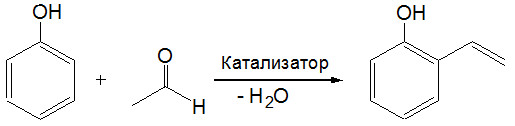

Получение винилфенолов путем каталитической конденсации фенола с ацетальдегидом

Впервые обнаружена и исследована ранее неизвестная реакция фенола с ацетальдегидом, позволяющая в одну стадию получать о-винилфенол.

Показано, что лучшим является катализатор, представляющий собой оксид хрома, нанесенный на γ-Al2O3 и модифицированный солями калия. Катализатор позволяет получать о-винилфенол с селективностью близкой к 100% по фенолу и 87%-ной селективностью по ацетальдегиду. Основной побочный продукт реакции, кротоновый альдегид, также является ценным химическим продуктом. Винилфенолы используются при получении лекарств, косметики и в качестве консерванта в пищевой промышленности. Полимеры на основе винилфенолов находят применение в производстве фоточувствительных материалов, антибактериальных средств и жидких кристаллов.

д.х.н., проф. Г.И. Панов, д.х.н. А.С. Харитонов,

к.х.н. М.В. Парфенов,

к.х.н. Л.В. Пирютко, к.х.н. И.Е. Сошников, к.х.н. Е.В. Староконь

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Новый способ получения триэтаноламина улучшенного качества

Разработан способ получения триэтаноламина (ТЭА) улучшенного качества, который широко применяется в различных отраслях промышленности, в том числе в производстве биоцидов, полупродуктов в синтезе лекарственных препаратов и парфюмерно-косметических средств. Реакцию аммонолиза оксида этилена проводят при температуре 110-150°C и давлении 2-15 МПа при подаче оксида этилена с одной стороны и воды с аммиаком с другой стороны, при мольных отношениях: аммиак/оксид этилена 1-2, вода/аммиак 5-15. Отличительной особенностью способа является проведение процесса в микроканальном реакторе проточного типа, содержащем камеру смешения и микроканальные пластины с каналами вытянутой формы, причем реактор имеет два входа: один для подачи оксида этилена, другой для подачи водно-аммиачной смеси. Подачу осуществляют непрерывно на входе в смеситель с последующим равномерным смешением в микроканалах при временах контакта 0,1-10 минут. Микроканальные пластины выполнены из металла, устойчивого к водно-аммиачной среде, при этом каналы в микроканальной пластине могут быть параллельными или взаимопересекающимися и могут иметь глубину и ширину от 0,2 до 2 мм. Способ позволяет повысить качество получаемого продукта – улучшить показатель цветности, а также повысить конверсию и селективность процесса.

академик В.Н. Пармон, д.х.н. Л.Л. Макаршин, д.т.н. З.П. Пай, д.х.н. Е.Г.

Жижина,

к.х.н. Д.В. Андреев, к.х.н. А.Г. Грибовский, к.х.н. Е.Е.Сергеев, Д.Ю. Ющенко

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Разработка процессов каталитического окисления органических соединений с применением экологически безопасных окислителей для получения импортозамещающих продуктов

Показана возможность получения востребованных, в том числе импортозамещающих продуктов тонкого органического синтеза – биологически активных веществ или их предшественников. Реакция двухфазного окисления органических субстратов перексидом водорода в присутствии бифункциональных металлокомплексных катализаторов Q3{PO4[WO(O2)2]4 протекает в органической фазе через транспорт кислорода от пероксокомплекса к субстрату. Показано, что метод межфазного катализа позволяет получать N-оксиды фосфоновых кислот с селективностью 85% при 90% конверсии субстрата (используются в производстве гербицидов) и карбоновые кислоты с высокими выходами 86-97% (используются в пищевой, медицинской и других отраслях промышленности).

д.т.н. З.П. Пай, к.х.н. Л.В. Малышева, П.В. Бердникова, Д.Ю. Ющенко

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Растворы Mo-V-фосфорных гетерополикислот в катализе: от синтеза к применению

Разработка и масштабирование способа получения модифицированных высокованадиевых растворов ГПК, обладающих высокой термостойкостью и быстро регенерируемых, обеспечила возможность создания на их основе технологичных катализаторов окисления субстратов разных классов.

Для новых растворов ГПК установлены зависимости физико-химических свойств (ρ, η,Е, рН) от степени восстановления и температуры. Подтверждено, что изменения свойств катализаторов полностью обратимы.

Результаты исследования открывают хорошие перспективы разработки в присутствии растворов Мо-V-Р ГПК процессов получения важных органических продуктов, например, диалкилбензохинонов и замещенных антрахинонов.

д.х.н. Е.Г. Жижина, к.т.н. Л.Л. Гогин, Ю.А. Родикова, д.т.н. З.П. Пай

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Исследование проникающей способности аэрозольных наночастиц с различными химическими свойствами поверхности в органы лабораторных мышей методом ускорительной масс-спектрометрии

В исследованиях проникновения органических аэрозолей в живой организм впервые в мире продемонстрирован метод прямой регистрации частиц при крайне низкой удельной дозе воздействия – зафиксировано 90 нг частиц в 1 г органа мыши при радиоактивности 0.6 Бк/г, а также при их вдыхании в естественных условиях.

Для получения меченых аэрозолей разработаны методы синтеза из 14С-метанола 14С-стирола, из которого затем получили полистирольные микросферы (в одном латексе – 225 нм, в другом – 80 нм). Из меченых латексов получали аэрозоль с низкой концентрацией, которым дышали мыши в течение 30 минут 5 дней. Изотопный анализ проб органов мышей методом сверхчувствительной ускорительной масс-спектрометрии показал, что частицы размером 225 нанометров в очень низкой концентрации (103 шт/см3), проникая в организм через лёгкие, накапливаются в почках, печени и мозге и при этом не накапливаются в сердце. Частицы размером 80 нм с концентрацией 104 шт/см3 вдыхаемого воздуха остаются в лёгких минимум полгода после воздействия.

Е.В. Пархомчук, А.И. Таратайко, Д.Г. Гулевич, А.М. Бакланов,

П.Н. Калинкин, А.Г. Окунев, С.А. Растигеев, В.А. Резников, В.В. Пархомчук,

Т.А. Трубицына, Е.А. Прокопьева, Е.И. Соловьева, Д.В. Кулешов,М.А. Кулешова

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск,

НГУ, ИОХ СО РАН, ИХКиГ СО РАН, ИЯФ СО РАН, НЦКЭМ СО РАН, ООО Тион

Нанесенные титан-магниевые катализаторы: новые данные о формировании и структуре активных центров и свойствах в полимеризации олефинов

Найдено, что нанесенные катализаторы состава TiCl4/MgCl2 (ТМК) с очень низким содержанием Ti (≤ 0,1 % масс.) обладают сверхвысокой активностью, более однородным составом соединений титана и являются удобной каталитической системой для исследования процессов формирования и структуры АЦ реальных нанесенных ТМК.

Методом препаративного фракционирования полипропилена (p-TREF) получены данные о влиянии содержания титана, предварительной обработки катализатора активатором (AlEt3) и введения внешнего донора на распределение АЦ по стереорегулярности при полимеризации пропилена. На основании этих данных предложены возможные структуры нестереоспецифических АЦ (алкильных соединений Ti(III), локализованных на грани (110) MgCl2) и схема их трансформации в АЦ с повышенной стереоспецифичностью.

д.х.н. Т.Б. Микенас, Е.И. Кошевой, М.И. Николаева, д.х.н. В.А. Захаров,

к.х.н. Л.Г. Ечевская, к.х.н. М.А. Мацько, к.ф.-м.н. А.А.

Шубин, к.х.н. А.А. Барабанов

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

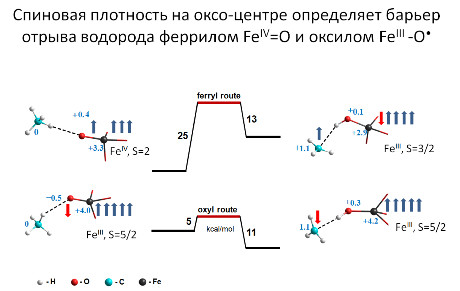

“Скрытая” радикальность комплексов феррил-иона FeO2+ как главный фактор активности в разрыве С-Н связей

Aктивация C-H связей FeIII-гидроксидами на группе [FeO]2+ в основном феррильном состоянии FeIV=O определяется “скрытым” возбуждённым оксильным состоянием FeIII-O•, которое может обеспечить сверхактивность такого центра, присущую свободным радикалам.

д.х.н. И.Л. Зильберберг, к.ф.-м.н. А.А. Шубин, к.ф.-м.н. С.Ф. Рузанкин,

В.Ю. Ковальский, Д.А. Овчинников, д.ф.-м.н., проф. Г.М. Жидомиров

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Получение мягких кислот Льюиса на основе фторированных органических соединений бора и исследование их каталитических свойств

Разработаны удобные способы получения органофторборанов, являющихся мягкими кислотами Льюиса, перспективными для использования в селективных гомогенных каталитических процессах. Органофторбораны могут быть получены в виде раствора в гексане путем взаимодействия стабильных и относительно легко получаемых калиевых солей органофторборатов с ионными жидкостями типа BMIM+Cl–·nAlCl3. На примере реакций алкилирования ароматических соединений показано, что получаемые органофторбораны являются мягкими кислотами Льюиса, селективно катализирующими алкилирование активированных субстратов. Установлено, что каталитические свойства органофторборанов определяются природой и количеством заместителей в окружении атома бора.

д.х.н. Н.Ю. Адонин, к.ф.-м.н. М.М. Шмаков, к.х.н. С.А. Приходько

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Исследования в области катализа, проведенные в Институте углехимии и химического материаловедения ФИЦ угля и углехимии СО РАН

Показана возможность целенаправленного регулирования физико-химических свойств катализаторов MnМW/SiO2 и MnМW-La/SiO2 (M = Na, K, Rb) и, соответственно, их активности в окислительной конденсации метана с образованием этана и этилена путем варьирования метода синтеза, типа щелочного металла и температуры прокаливания. Определен состав оптимального катализатора 2 мас. % Mn 0.8% Na 3 мас. % W/SiО2.

Разработаны и испытаны капиллярные микрореакторы непрерывного действия с новыми каталитическими покрытиями в селективном гидрировании 2-метил-3-бутин-2-ола. Исследована кинетика реакции на покрытиях Pd/(Ti,Ce)O2, Pd80Zn20/(Ti,Ce)O2 и Pd/TiO2.

Разработана методика синтеза препаратов аминозамещенного силанола в виде растворенных аморфных частиц около 1 нм, устойчивых к агрегации, адаптированных для иммобилизации фрагментов ДНК. Разработанные частицы являются новым типом систем доставки терапевтических ДНК в клетки и впервые будут использованы для создания нанокомпозитов, способных селективно воздействовать на внутриклеточный генетический материал.

Приготовлены Cu-катализаторы, нанесенные на диоксид титана, в виде активированной механической смеси, содержащей наноразмерный рутил и анатаз. Катализаторы исследованы методами РФА, БЭТ, ЭСДО и ЭПР. Показано, что наличие фазы рутила улучшает каталитические свойства Cu/TiO2 в реакции DeNOx при низких температурах.

Проведены промышленные испытания установки одностадийной каталитической очистки попутного нефтяного газа от сероводорода. Эффективность очистки более 97%. АО «СМП-НЕФТЕГАЗ», Республика Татарстан.

Введена в эксплуатацию промышленная установка каталитического окисления сероводорода в элементарную серу. АО «Конденсат», Республика Казахстан.

Разработаны каталитические блоки сотовой структуры, для очистки дымовых газовов от оксидов азота и серы, введена в эксплуатацию полупромышленная установка по каталитической очистке дымовых газов тепловых электростанций угольной генерации.

Разработан метод гидрогенизации барзаских углей при температуре 350-400°C на наноразмерном никельмолибденовом катализаторе с целью получения жидких продуктов в автоматизированной автоклавной установке при 50-55 атм. Получены предварительные данные о механизме превращения органической массы углей.

чл.-корр. РАН З.Р. Исмагилов

Институт углехимии и химического материаловедения ФИЦ УУХ СО РАН, г. Кемерово

Разработка и усовершенствование промышленных катализаторов и технологий

Создание технологии производства импортозамещающих катализаторов глубокой гидропереработки вакуумного газойля

Разработаны новые катализаторы, позволяющие обеспечить глубокую переработку нефтяного сырья: CoNiMo(ИК) для процессов гидроочистки вакуумного газойля (ВГО) и алюмосиликатный катализатор гидрокрекинга ВГО. Катализатор глубокой гидроочистки ВГО дает возможность получать сырье для каталитического крекинга, содержащее 200-500 м.д. серы при температуре гидроочистки на 5-20°C ниже и с выходами целевых продуктов на 4-13% больше, чем на современных импортных и отечественных катализаторах. Алюмосиликатный катализатор гидрокрекинга ВГО позволяет по сравнению с известными импортными катализаторами увеличить выход дизельной фракции на 4-5%, снизить уровень газообразования ниже 3%, уменьшить себестоимость в полтора раза за счет меньшего содержания Ni и Mo(W) в катализаторе.

академик В.Н. Пармон, д.т.н. А.С. Носков, к.х.н. О.В. Климов

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Упрощенная технология получения и переработки реакторного порошка сверхвысокомолекулярного полиэтилена

Разработана новая упрощенная технология получения и переработки реакторного порошка сверхвысокомолекулярного полиэтилена (РП СВМПЭ) в сверхпрочные и сверхмодульные изделия (пленки и пленочные волокна) методом твердофазной переработки. Рассмотрение технологии полимеризации и технологии переработки РП СВМПЭ в одном ключе позволило учесть формирование нужной морфологии и наноструктуры получаемых РП для стадии твердофазной переработки. Наработана укрупненная партия РП СВМПЭ, уточнены требования к размеру и плотности РП. Реализована стадия переработки с получением волокон с прочностью 3,3-3,6 ГПа и модулем 120-150 ГПа. Разработка защищена тремя патентами РФ. Разрабатываемая технология отличается оригинальностью и не имеет аналогов в производстве.

чл.-корр. РАН С.С. Иванчев

Санкт-Петербургский филиал Института катализа им. Г.К. Борескова СО РАН, г. Санкт-Петербург

Разработка российского аналога нового поколения перфторированных мембран

Для водород-кислородных топливных элементов, предназначенных для использования в наземной, подводной и воздушной технике, разработан российский аналог нового поколения перфторированных мембран типа Aquivion, работающих при более высоких температурных условиях, чем мембраны Nafion (фирма DuPont, США), и испытан в мембранно-электродных блоках в Крыловском государственном научном центре. Изучены особенности тонкой структуры мембран типа Aquivion и условия оптимизации их протонной проводимости.

чл.-корр. РАН С.С. Иванчев

Санкт-Петербургский филиал Института катализа им. Г.К. Борескова СО РАН, г. Санкт-Петербург

Каталитическая очистка отходящих газов от летучих органических соединений на катализаторах Pt/стекловолокно

Исследован процесс очистки отходящих газов от летучих органических соединений на платино-стекловолокнистых катализаторах.

Наработана партия катализатора 0.012%Pt/СВ с низким содержанием платины, которая успешно эксплуатируется на ПАО «Нижнекамскнефтехим» в дожиге летучих органических соединений в отходящих газах завода СКИ, обеспечивая уровень очистки не менее 99.99%.

к.х.н. Е.В. Ковалев, к.х.н. А.П. Сукнев, д.х.н. Б.С. Бальжинимаев

Институт катализа им. Г.К. Борескова СО РАН, г. Новосибирск

Экспериментальная оптимизация на пилотной установке нового процесса комплексной переработки биомассы березы в биотоплива и ценные химические продукты

В продолжение исследований по созданию фундаментальных основ процесса комплексной переработки биомассы березы (древесина, кора) в биотоплива и ценные химические продукты проведена экспериментальная оптимизация на пилотной установке стадий каталитического фракционирования древесины с получением ксилозы, микрокристаллической целлюлозы (МКЦ) и растворимого низкомолекулярного лигнина, каталитической деполимеризации МКЦ с получением глюкозных гидролизатов для синтеза биоэтанола, выделения биологически активного бетулина и суберинового связующего из бересты, получения твердых биотоплив с использованием связующих на основе лигнина и суберина, получения энтеросорбента из луба коры березы.

Наработаны опытные партии ксилозы, МКЦ, биоэтанола, бетулина, твердого биотоплива, энтеросорбента и проведены их исследовательские испытания. Разработан технологический регламент процесса комплексной переработки биомассы березы. Преимущества нового процесса по сравнению с аналогичными разработками: обеспечивается утилизация всей биомассы березы, включая лигнин и кору (тогда как в традиционных технологиях перерабатываются только полисахариды), что делает процесс безотходным; наряду с биотопливами нарабатываются продукты с высокой добавленной стоимостью из коры и лигнина, что снижает себестоимость производства биотиплив; в технологическом цикле отсутствуют токсичные, экологически опасные и коррозионно-активные реагента, что позволяет снизить, по сравнению с традиционными технологиями, затраты на утилизацию отходов и на мероприятия по охране труда и окружающей среды.

д.х.н. Б.Н. Кузнецов

Институт химии и химической технологии СО РАН, г. Красноярск

Разработка катализаторов гидроочистки. Проектирование катализаторной фабрики в г. Омске

По результатам НИР “Разработка энергоэффективной технологии селективной гидроочистки бензинов каталитического крекинга с сохранением октанового числа” был разработан катализатор CoMoS/CoSx/SiO2 и на его основе технология селективной гидроочистки бензина каталитического крекинга, реализуемая по схеме с предварительным гидрированием диеновых углеводородов и последующим его разделением на легкую и тяжелую фракции в ректификационной колонне. Тяжелая фракция далее подвергается селективной гидроочистке в двух параллельных реакторах. Для разработанной технологической схемы выбрано технологическое оборудование.

Осуществляется проектирование катализаторной фабрики в г. Омске (АО “АО Газпромнефть-ОНПЗ”), позволяющей получать отечественные современные катализаторы гидрокрекинга, гидроочистки, каталитического крекинга.

Проектирование и строительство опытно-промышленной установки гидроконверсии гудрона на наноразмерном катализаторе мощностью 50 тыс. т/год на АО “Танеко”.

Проектирование современной установки по получению нафтила на ООО “Газпромнефтехим Салават”.

д.т.н., проф. В.М. Капустин

ОАО «ВНИПИнефть», Москва

Катализаторы эпоксидирования пропилена

Получены молибденовые катализаторы эпоксидирования пропилена гидропероксидом этилбензола на основе пероксида водорода и порошкообразного молибдена с использованием гликолей, а также спиртового раствора пероксида циклогексанона (1,1'-диоксидицикло-гексилпероксида) и молибденового порошка, обладающие высокой стабильностью и селективностью. Опытно-промышленные испытания, проведенные на пилотной установке эпоксидирования цеха №1122 НТЦ ПАО «Нижнекамск-нефтехим», показали, что эти катализаторы обеспечивают режим мягкого протекания реакции эпоксидирования пропилена, без резкого повышения температуры и давления в начале процесса, как это характерно для заводского комплексного молибденового катализатора (КМК). Новые катализаторы обеспечивают получение сопоставимых с КМК технологических показателей эпоксидирования пропилена: конверсия ГПЭБ 97%, селективность по оксиду пропилена 82%. Применение данных катализаторов вместо КМК позволит высвободить гидропероксид этилбензола из стадии приготовления катализатора и получить дополнительное количество оксида пропилена.

д.х.н., проф. Х.Э. Харлампиди

Казанский национальный исследовательский технологический университет, г. Казань

Катализатор и процесс синтеза дивинила из этанола; прочностные свойства катализаторов

Отработана технология производства катализатора для синтеза дивинила из этанола в промышленных условиях. Приготовлена опытная партия катализатора. Смонтирована полузаводская демонстрационная установка синтеза дивинила из этилового спирта для отработки технологических параметров процесса.

Методами термогравиметрии, рентгеноструктурного анализа, физико-механических испытаний изучалось влияние различных факторов (используемое сырье, технологические параметры и др.) на механическую прочность пылевидных катализаторов на основе оксидов алюминия для процессов дегидрирования изобутана и пропана и гранулированных катализаторов на основе оксидов железа для процесса дегидрирования этилбензола. Изучены основные закономерности формирования прочностных свойств алюмооксидных и железооксидных катализаторов; предложены рецептура и технологии производства катализаторов дегидрирования этилбензола с улучшенной на 80-100% механической прочностью.

д.т.н., проф. Г.Р. Котельников

ОАО НИИ «Ярсинтез», г. Ярославль

Исследование воздействия метилдиэтаноламина (МДЭА) на активированные никелевые катализаторы метанирования

В процессе эксплуатации агрегатов по производству аммиака большой единичной мощности наблюдаются уносы абсорбентов диоксида углерода в реактор метанирования. Это может приводить к увеличению газодинамического сопротивления и снижению каталитической активности.

Комплексом физико-химических и физико-механических методов исследованы характеристики и изучена каталитическая активность Ni-Al катализатора НИАП-07-01 (НКМ-1), Ni-цементсодержащего катализатора НИАП-07-07 (НКМ-7), а также ряда импортных контактов, как в их исходном состоянии, так и активированных с последующим воздействием на них водного раствора МДЭА в протоке азотоводородной смеси (АВС). Показано, что исследуемые катализаторы после воздействия на них водного раствора МДЭА в протоке АВС, в отличие от водного раствора поташа, практически сохраняют высокие значения механической прочности, общей удельной поверхности, пористости и каталитической активности. Обнаружено, что в процессе воздействия при температуре 320°C на активированные катализаторы водного раствора МДЭА в протоке АВС происходит их пассивация, сопровождающаяся повышением температуры и снижением активности. Установлено, что поверхность катализаторов блокируется МДЭА. Регенерация активированных катализаторов метанирования, подвергшихся воздействию водного раствора МДЭА, должна осуществляться путем их сушки в протоке АВС с последующим довосстановлением.

д.х.н., проф. Е.З. Голосман, к.т.н. В.Н. Ефремов

ООО “НИАП-КАТАЛИЗАТОР”, г. Новомосковск

Использование цементсодержащих катализаторов для получения аминов

Изучено влияние способа приготовления Cu-Zn- и Cu-Mg-содержащих композиций, синтезированных с использованием алюминатов кальция (талюма), в частности, последовательности внесения компонентов, на эффективность их каталитического действия в реакции аминирования н-бутанола. Лучшие результаты достигнуты при формировании катализаторов из двойной сложной соли на основе смешанных гидроксокарбонатов Cu-Zn или Cu-Mg. Установлено, что Cu-Mg-содержащие образцы уступают в эффективности каталитического действия Cu-Zn-аналогам.

На лучшем из Cu-Zn-цементных образцов исследована возможность влияния внешней диффузии на процесс гидроаминирования н-бутанола аммиаком с преимущественным образованием дибутиламина.

Предложен новый способ синтеза бутиламинов, в особенности с существенным преобладанием дибутиламина, с использованием модифицированных промышленных никельалюмокальциевих катализаторов другого назначения, известных под марками НКМ 4А и НКМ-7, компоненты в которых находятся в оксидной или солевой форме, соответственно. В оптимальных условиях на указанных контактах достигается конверсия бутанола на уровне аналога при селективности по дибутиламину примерно в 1,4 раза выше в сравнении с последним.

На экспериментальных и промышленных образцах Cu- и Ni-содержащих катализаторов исследованы основные направления превращений 2-этоксиэтанола в парофазной реакции его гидроаминирования аммиаком. Установлено, что никелевые катализаторы на алюмокальциевой основе имеют заметное преимущество в производительности по 2-этоксиэтиламину перед контактами на других носителях.

к.х.н. В.В. Белов

ГВУЗ “Украинский

государственный химико-технологический университет”, г.

Днепропетровск

д.х.н., проф. Е.З. Голосман

ООО “НИАП-КАТАЛИЗАТОР”, г. Новомосковск

Катализаторы для процессов гидроочистки, каталитического крекинга и риформинга

Реализованы проекты по импортозамещению катализаторов для процессов гидроочистки средних дистиллятов, катализаторов каталитического крекинга, каталитического риформинга и изомеризации на действующих мощностях Компании КНТ Групп и на вновь построенных в последние годы предприятиях (производство катализаторов для этих процессов в ОАО “Газпромнефть-Омский НПЗ”). На мощностях Компании КНТ Групп начат выпуск катализаторов гидрокрекинга и идет поиск применения их вместо импортных катализаторов. На ПАО “Нижнекамскнефтехим” и химзаводе им. Л.Я. Карпова (г. Менделеевск) ведутся исследовательские работы по организации производства катализаторов дегидрирования нормального бутана.

д.х.н. Р.С. Яруллин

ОАО "Татнефтехиминвест холдинг" г. Казань

Разработка отечественных каталитических технологий для производства высококачественных и экологически чистых сортов автобензинов

Создание отечественной технологии каталитического риформинга с непрерывной регенерацией катализатора для производства высококачественных автобензинов. Завершена разработка промышленной технологии производства катализатора для установки риформинга с непрерывной регенерацией. Выпущена первая промышленная партия катализатора RC-12. Проекту присвоен статус национального (Протокол № АТ-646пр от 20.12.2016 г.).

Создание технологии изомеризации С7-фракции для обеспечения производства экологически чистых сортов автобензинов (Изомалк-4). Проведены исследования по разработке промышленной технологии производства катализатора и технологии изомеризации С7-фракции. Разработана промышленная технологическая линия для производства катализатора изомеризации С7-фракции СИ-4. На заседании рабочей группы Минэнерго России отмечена актуальность разработки технологии изомеризации С7-фракции для производства экологически чистых сортов автобензинов.

к.х.н. А.Н. Шакун

ОOO “НПП Нефтехим”, г. Краснодар

Способ получения полупродукта присадки “Детерсол” путем алкилирования салициловой кислоты α-олефинами С16-С18 в присутствии макропористого сульфокатионита

Разработан новый способ получения полупродукта присадки “Детерсол” путем алкилирования салициловой кислоты α-олефинами С16-С18 в присутствии макропористого сульфокатионита. Промышленный сульфокатионит подвергается предварительной осушке и загружается в реактор. Сырьевая смесь высокомолекулярных олефинов с салициловой кислотой в заданном соотношении в интервале 1:1,05 – 1:1,14 смешивается в аппарате с мешалкой, нагревается до необходимой температуры и подается в реактор насосом, производительность которого обеспечивает время пребывания в реакторе от 3,0 до 30,0 ч. Процесс идет с высоким выходом (около 90%) и практически 100% селективностью. После выхода из реактора реакционная масса остужается и осуществляется анализ ее состава. В дальнейшем проводится очистка реакционной массы от не вступившей в реакцию салициловой кислоты методом вакуумной ректификации.

Преимуществом предложенного способа является получение алкилсалициловой кислоты в одну стадию. В процессе алкилирования олефиновый компонент полностью вступает в реакцию, практически отсутствуют продукты алкилирования ароматического кольца салициловой кислоты двумя молекулами высокомолекулярного олефина. Процесс не требует для его протекания каких-либо растворителей, что позволяет упростить отгонку непрореагировавших компонентов и снизить параметры этого процесса. Чистота целевого продукта оказывается более 99% масс.

д.т.н. А.В. Тыщенко

ПАО “Средневолжский НИИ по нефтепереработке”, г. Новокуйбышевск

19-23 сентября 2016 г., Лондон, Великобритания

http://conf.ict.nsc.ru/CR_22/en

19 - 23 сентября 2016 года в Лондоне прошла XXII Международная конференция по химическим реакторам ХИМРЕАКТОР-22. Конференция была организована Институтом катализа им. Г.К. Борескова СО РАН (Россия) совместно с Университетским колледжем Лондона (Великобритания). Традиционно она проводилась под эгидой Европейской Федерации по химической технологии (EFCE).